ESMA Inc. - Industrial Parts Cleaning Equipment:

Parts Cleaning: Automated Cleaning Systems

**We move the liquids - NOT the parts!

Here at ESMA Incorporated we have been in the ultrasonic cleaning business for over 40 years and we are known for our high quality, top of the line ultrasonic washers and cleaners. Our automated systems are unique due to our innovative process in which automation is done by moving the liquids rather than the basket of parts. This allows for a lower cost automated system as opposed to competitor system which use robotic gantry systems to move baskets from tank to tank. These systems also have a much smaller footprint than competitor automated systems.

Our automated washers can be standalone units which utilize facility water and drain for the fluid transfer, or integrated systems equipped with heated storage tanks which store and filter the different solutions for reuse in subsequent cycles.

We have four standard sizes of automated ultrasonic cleaning systems in order to fit virtually any application big or small. Custom sized equipment is also available to fit the individual customer needs as well.

Automated Cleaning Systems:

E700 | E889 | E992

Non-automated Cleaning Systems:

Single-chassis, multi-chambered: E386 | E782

Multi-chassis, or Single-chassis: E188 | E283 | E888

The E1002 automatic ultrasonic cleaning system is the smallest version of our standalone automated washers and offers a tank size of 3.5 gallons and ultrasonic power of 600 watt. This system provides multi-functional wash, rinse and hot-air drying.

The ESMA E889 is our large standalone ultrasonic washer which holds 18 gallons and has an ultrasonic power of 1800 watts; this system is designed to make the cleaning process simpler. The E889 ultrasonic cleaner uses a PLC to control the cycles of cleaning, rinsing and drying. We are proud to say that this system offers improved finished part quality and low cost automation of the aqueous cleaning process.

Our E700 version offers a tank volume of 9 gallons and an Ultrasonic power of 1200 watts, this is an integrated system incorporating heated storage tanks for reuse of cleaning solution and/or rinse water. The working tank is a console mounted PLC-controlled system that offers automated clean, rinse and dry phases. By filtering the solution and/or rinse water, these materials can be reused with each cycle; overall the E700 system offers reduced operator involvement and speeds up the process.

Our E992 automated ultrasonic passivation system has a tank volume of 18 gallons and an ultrasonic power of 1800 watts, this cleaning system is self-contained and fully automatic utilizing 4 heated storage tanks to house alkaline detergent, passivation acid and DI rinse water. Parts processed in this system are ultrasonically cleaned, rinsed, passivated, rinsed and dried in order to ensure cleanliness and proper passivation. The operator is able to control the system through a touch screen interface, meaning minimal exposure to acids or cleaned parts and the solutions are housed in closed, covered tanks to minimize environmental fumes. This closed-process passivation system is designed to clean, rinse, passivate, re-rinse and dry parts automatically.

So no matter your application or goal, you’ll be sure to find an ultrasonic cleaning system that fits your application. If you are unsure of which product is best for your unique specifications, contact us today and we would be happy to point you in the right direction. Here at ESMA we move the liquids, not the parts.

Ultrasonic Cleaning Solutions

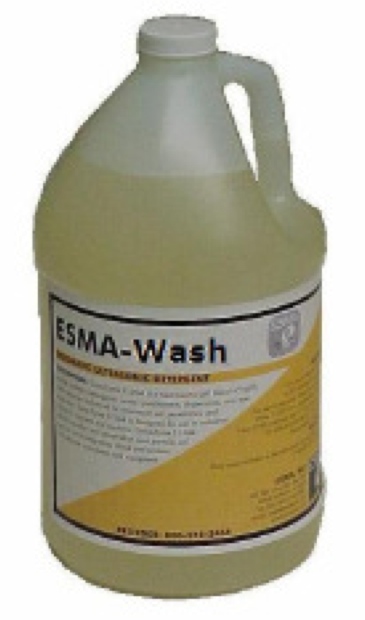

Ultrasonic Cleaning SolutionsESMA brand ultrasonic cleaning detergent solutions are uniquely formulated to aid ESMA ultrasonic cleaning equipment in the removal of oil, dirt, particulate, residue, flux, and solvents from top surfaces, internal bores, and blind cavities of industrial parts. ESMA ultrasonic solutions are available for use on rubber and all metals including polished aluminum, zinc, stainless steel, copper, brass, and ferrous metals.

General Purpose | Compound Removers | Metal Wash

Contact ESMA

Customer Service and Sales

Toll Free: (800) 276-2466

Phone: (708) 331-1855

Fax: (708) 331-8919

Technical Support

Toll Free: (800) 276-2466

For any operational, maintenance or engineering questions.

ESMA Inc.

Corporate Headquarters

16672 State St.

South Holland,

IL

60473

USA

Phone:

(708) 331-1855

Email:

sales@esmainc.com